MEDICAL Devices

MEDICAL Devices

Overview

I began my career in the medical device industry in January of 2016 when I started my first development engineering co-op at Zimmer Biomet, a worldwide leader in innovative orthopedic device solutions. Supporting the Patient-Matched Implants Team (PMI) led to many opportunities for me to contribute solutions to real, cases of abnormal bone loss and deformity. Here, I did everything from creating X-ray image overlays to authoring surgical techniques and designing custom orthopedic implants and surgical instruments.

Working closely with surgeons, machinists and other engineers, I used segmented CT scans, several powerful computer-aided design software and a cutting-edge haptic feedback device to design implants tailored to each patient's unique anatomy.

iMPACTED ANATOMY

Patient-Specific Implant Case Breakdown

During my eight months of work for PMI, I supported 13 engineers on over 100 cases. My casework impacted over 100 patients with affected anatomy spanning the majority of the human body.

CASEWORK

TRANSACRAL SCREW VARIABLE TILT & TRANSLATION DEVICE

Try moving the slider for a before and after comparison.

- Left Image: Segmented CT scan of pelvis and projected resection

- Right Image: X-ray image of pelvis and implant post-operation

This was a first of its kind oncology case in Poland where the tumor and two-thirds of the patient's hemi-pelvis (shown in red) were resected and replaced with a modular patient-matched implant. I designed the Variable Tilt and Translation Device (V-TAT) that the surgeon used to mitigate the risk of severing the spinal cord or puncturing the bladder when fixating the transacral screws. In addition to designing the V-TAT, I also made a detailed surgical technique for this case that can be found at the bottom of this page.

Case Engineering Mentor & Designer of the Modular Hemi-Pelvis Implant: Andriko Telka

Triflange with Retaining ring & Suture Augments

Try moving the slider for a before and after comparison.

- Left Image: Segmented CT scan of pelvis and projected resection

- Right Image: X-ray image of pelvis and implant post-operation

This was another oncology case where the tumor and the patient's surrounding anatomy were resected and replaced with a custom titanium acetabular triflange implant. My design included a retaining ring for hernia-prevention as well as porous suture augments to encourage biologic ingrowth and fixation.

Case Engineering Mentor: Nicholas Horsmon

Hip

Hip

Knee

Knee

Extremities

Extremities

Surgical Instruments

Surgical Instruments

Surgical Techniques

Surgical Techniques

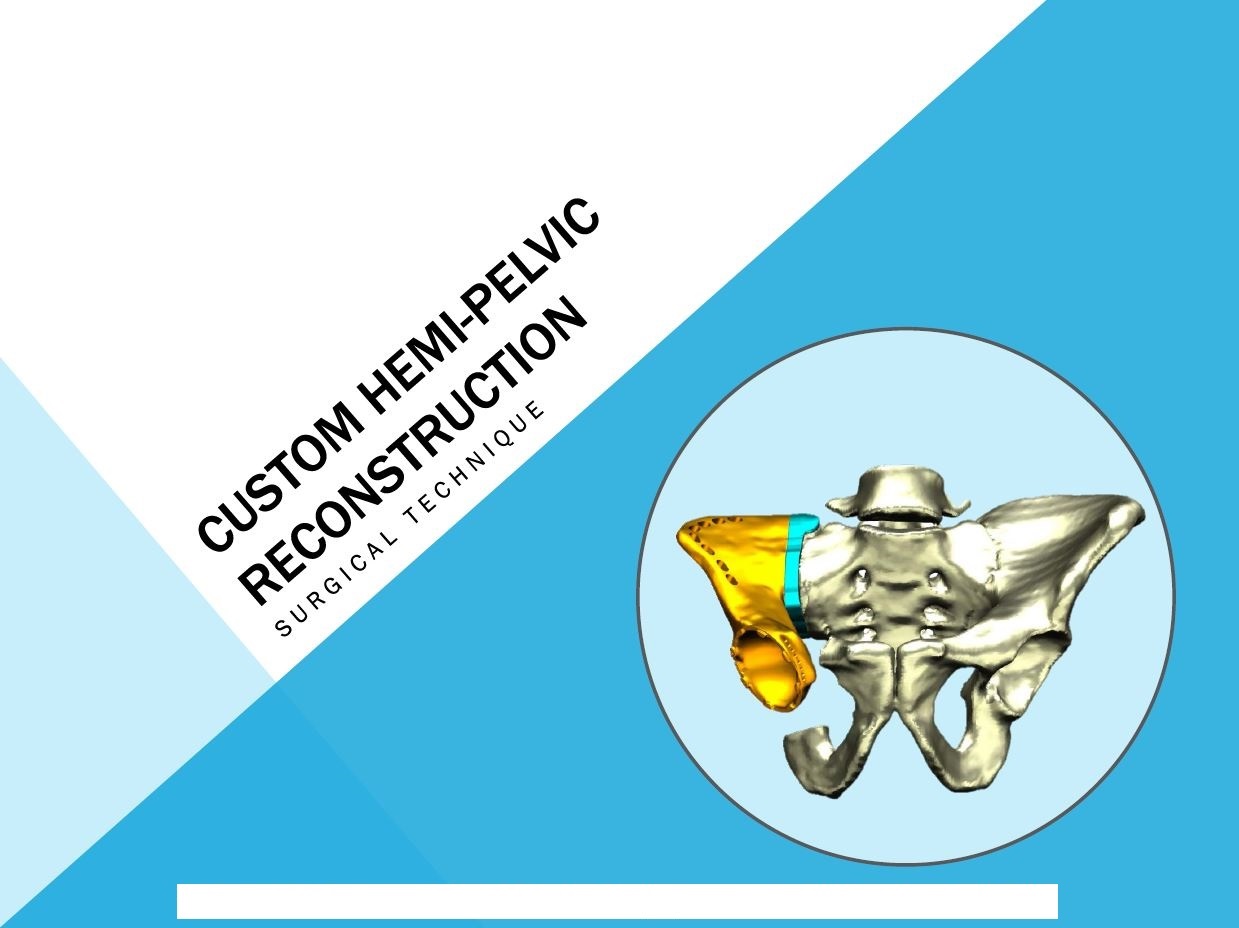

These are pages from the surgical technique I made for the example case I included above. Given the fact that this case was outside of the US, I also made an animated guide in addition to authoring this technique, to help mitigate any confusion caused by the language barrier.

These are pages from the assembly guide I made for the PHASTA device I designed. The device in combination with this set of instructions will allow patients with a transdermal compress implant to use prosthetic hook arm sockets and a variety of other prostheses.